We created a new class in the Design & Management program in the School of Design Strategies to run in Fall 2011; Small Business Enterprise: DEED.

The goal of this class is to sell the products of the artisan groups DEED works with. The first challenge to be addressed is to create a legal structure through which the products of the artisans can be imported and sold in the USA. The ultimate goal for DEED is to sustain itself by generating income both for the artisans and for the activities of DEED. The mission of DEED is two fold, one is to support the artisans to develop income generating activities, sustaining themselves through their crafts and secondly, to provide as many real world hands-on learning experiences as possible for students and faculty from all over the New School.

In preparation for the class we provided the women of Ajkem’a Loy’a and Barco with a small stipend to develop a new product line for the students to work with. In August I traveled to San Lucas Toliman for 8 days together with Rachel Young and Shari Diamond to meet with the women, see the products they had developed, further develop their new product lines as needed and create ‘look books’ for both the women and DEED. The ‘look books’ will serve as a tool to facilitate communication between the students and the women about the products.

Rachel Young is a rising senior in the Integrated Design program and was in the DEED Spring class ‘Designing Development’. Shari Diamond is a full-time Parsons faculty member and a professional photographer. Maria Jose, the DEED intern in Guatemala, joined us for one day.

When we arrived on Friday in San Lucas Toliman, we had an appointment to meet with the women of Ajkem’a Loy’a. It was very nice to see them again and to introduce the group to Rachel and Shari. We asked the women to share with us the products they had developed using the stipend. They showed us three new scarves, which were color variations on products they had made before. I was slightly disappointed and expressed my concern that they didn’t develop new designs, which would distinguish Ajkema’s Loy’a products from the products already available on the market? We discussed the importance for them to distinguish themselves. I showed Shari and Rachel the products developed in earlier design workshops with Ajkem’a Loy’a and we all agreed that we would make a selection for a product line based on all products they had made over time. We put together a collection of 10 pieces consisting of bags and scarves. We went over all products together and spoke about price point and how some of the bags could drop in price if they eliminated some of the seams and found less expensive leather from another source. Sandra of Ajkem’a Loy’a was sure we could lower the current price 30%. The price point is determined by adding the hourly fair wage of the women and the cost of materials.

We agreed that we would all meet again on Monday morning. Maria Jose, our intern from Guatemala City would join us to further facilitate our conversation. It was the first time for me to meet Maria Jose and she proved to be a wonderful mediator. We agreed that the women would begin making samples of color variations of the scarf designs we selected. Sandra would finish a weaving she had started to become a simple tote bag.

The conversation we had with Ajkem’a Loy’a and Maria Jose on Monday was very valuable and insightful. We were able to clear up some misunderstandings and the women were able to express their concern with the lack of sales of their products. They are happy to work with us but it is also a time investment on their side, and that explained the little new product development they had done. They didn’t see themselves selling their products in their own market. Their products are too expensive and they don’t feel they have access to a high-end market.

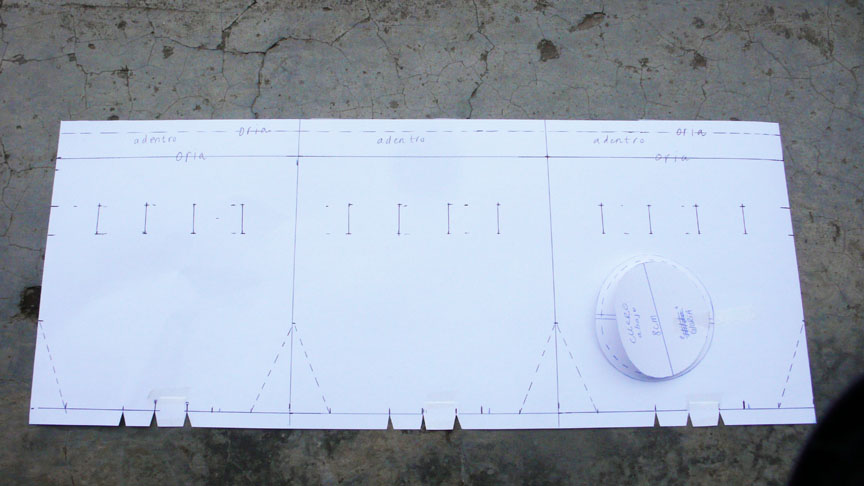

Preparing the products, patterns and the ‘look book’ for the reproduction.

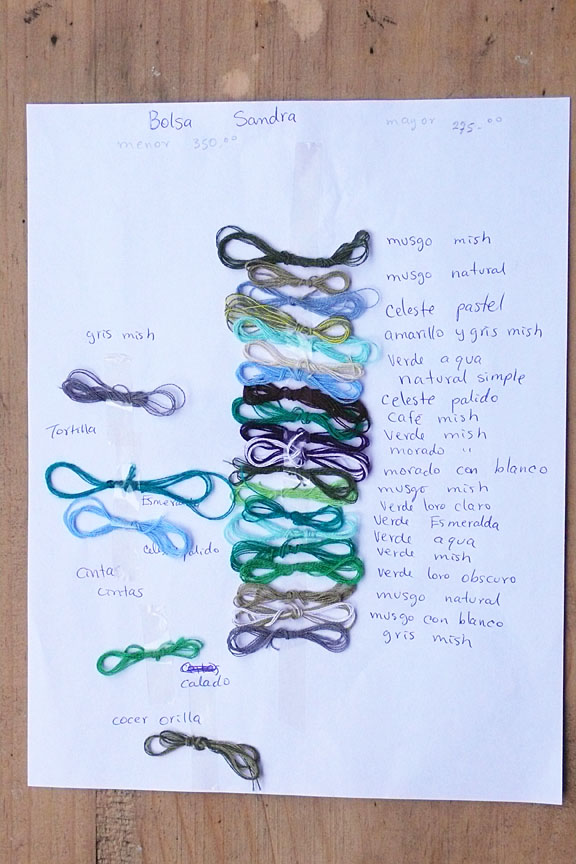

On Saturday morning we met with Barco. I was happily surprised to see how the group had grown. The atmosphere was one of joy, we exchanged happy hugs and I introduced Shari and Rachel to the women. In the garage of Teresa’s house, weaving threads were hanging from lines that stretched across the ceiling. Some yarn was still wet while others had dried already. With the stipend, the women of Barco had bought many different kinds of threads, including curly and straight simple threads. They were naturally dyed in a huge variety of colors and shades and it was a delightful sight. There were quite a few new women I had never met before and it was a joyful reunion. Each woman had created a scarf and all the scarves were lying on a table positioned to the side of the room.

We looked at all the scarves individually; we had no idea who made which scarf and it seemed the women were happy to present them collectively. Shari, Rachel and I discussed briefly how we would proceed and we decided that we would each pick 4 scarves we really loved and continue from there. This resulted in a very mixed selection, which we believed was great. Perhaps we each represented a different type of customer though some scarves we all agreed on. Barco enjoyed our selection; we had picked scarves made by different women in the group. We asked the women to produce a second version of their scarf so that they could keep an original design and that we could take a sample to New York. We selected a different combination of colors for each scarf together with the women, choosing from the abundance of threads that were hanging from the garage ceiling.

Duplicating the original scarves proved challenging. Even though the same woman wove the same scarf, some scarves came out completely different. We discussed the differences with the women once the second scarves were finished. In most cases it resulted in a beautiful variation so we included it as a new sample in the ‘new collection’. Both Dora and Teresa understood the notion of replicating a product as a condition required by the current market economy, and will work with the group once an order is placed.

We also discussed the tactile quality of the scarves; one scarf in particular was very soft and supple. I asked Dora about it and she explained that it was woven in a technique that her sister Eufemia invented. We agreed that from now on all scarves would be woven like that. Dora called in ‘suave’, soft.

all photographs by Shari Diamond

Pascale